There are a variety of Thermal Interface Materials (TIMs) on the market with thermal conductivity values as high as 15 W/mK.

We have developed a prototype formula that raises the bar to 120 W/mK*.

The use of modern TIM (Thermal Interface Materials) formulations with high thermal conductivity could revolutionise the market for electronic devices that generate large amounts of heat. Increasing their performance and extending their service life is possible with formulations based on innovative materials and nanotechnology.

The global conductive materials market size is calculated to be USD 1.84 billion in 2021 and is expected to have an estimated growth rate (CAGR) of 10.5% during 2023-30.

Possible industries where the new TIM formulations may have applications include photovotaics, military, medical, transport, energy and electronics in devices such as radars, guidance systems, CT scanners, MRI machines, ultrasound, computers, smartphones, energy banks and home electronics.

TIM Research & Development

There are a variety of TIM (Thermal Interface Materials) on the market with thermal conductivity values in the range of 3 - 15 W/mK.

Modern electronic components require much better cooling parameters. The use of additional means, such as high-efficiency fans, water coolers, etc., are very effective, but they take the generated heat away from the emitting components (acting partly as heat sinks) - so the question of generated heat output remains open and relevant.

We have ready-made prototype innovative TIM products in the thermal conductivity range of 15 - 40 W/mK.

Our R&D work has shown that it is possible to develop TIM materials with thermal conductivity values of 40 - 60 W/mK and even higher values >120 W/mK*

* Confirmed by Berliner Nanotest und Design GmbH

THERMAL MANAGEMENT

One of the biggest problems currently encountered in electronics is the effective removal of heat generated by device components: microprocessors, diodes, transistors, LEDs.

In order for heat removal to be effective, it must take place through as much of the contact surface as possible between the active component and the heat sink. The materials that fill the contact surface (TIM - Thermal Interface Materials) are designed to conduct heat as efficiently as possible.

Made on the basis of organic adhesives with inorganic fillers (silver powders or flakes due to silver's high thermal conductivity value of more than 420 W/mK), they are mostly thermally cured or sintered, resulting in a permanent connection between the components (figure on the right).

The organic components of these materials (polymers) limit the thermal conductivity parameters to a large extent. Our R&D work is moving in the direction of reducing the proportion of organic components and developing innovative thermally conductive compositions based on silver fillers with different levels of fineness (micro and nano).

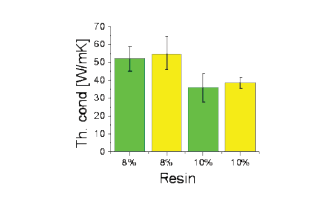

Test results of prototype TIM materials show several times better thermal conductivity values at bonding polymer (epoxy resin) values of 8% and 10% (by weight).